|

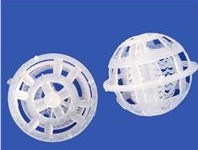

Plastic cage ball has excellent characteristics,

1. large voidage,

2. heat resistance,

3.chemical corrosion resistance,

4.low pressure drop and mass transfer unit height,

5. high pan-point,

6.vapor and liquid contacted fully,

7.small proportion,

8.high mass transfer efficiency

In a variety of media,the operation temperature is 60-150,Plastic cage ball is widely usded in the packing tower in pertroleum,chemicals,chlor-alkaki,gas and environmental industries.Besides,Plastic cage ball can be usded in a variety of horizontal acid tanks and condensate and desalting water tanks in water treatment.Plastic cage ball reduces the heat loss in large extent and the pullution of dioxide carbon and oxygen o water in acid mist and air,and protects operator's health,so as to maintain the water quality,save energy and clean up the environment.

Plastic cage ball can be usded in a variety of horizontal acid tanks and condensae and desalting water tanks in water treatment.Plastic cage ball reduces the heat loss in large extent and the pollution of dioxide carbon and oxygen to water in acid mist and aire.

Technical specification for Plastic cage ball:

|

Type

|

Diameter ×Height ×Thickness mm

|

specifific surface area m2/m3

|

Void Volume

%

|

Heaping Weight

Kg/m3

|

No.of elements n/m3

|

Packing

factor m-1

|

|

38

|

38×1.2

|

96

|

88

|

110

|

22000

|

141

|

|

50

|

50×1.5

|

82

|

90

|

88

|

10480

|

112

|

|